Expanding Opportunities in the

Field of Metal-Organic Compounds

Who We Are

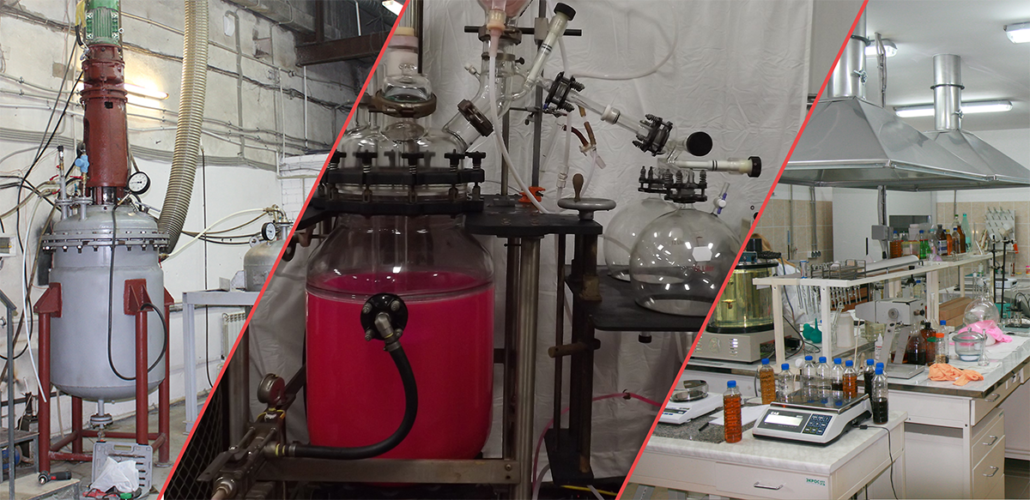

Founded in 2010, our business has flourished over the past decade to become a competitive supplier and innovator of specialty organic, inorganic and organometallic compounds targeted primarily for advanced material coatings, composites, and catalyst applications. Our products support the largest manufacturers and OEM customers in the semiconductor and industrial coatings industries. We partner with companies around the world to provide rapid metal-organic molecule development, scaling from small-sample feasibility analysis through High Volume Manufacturing.

Why Join Us

Our success is driven by our tight-knit team of talented employees and our customer-first mentality. At Ereztech, we’ve built an environment where innovation and creativity are both recognized and encouraged. Joining our team means that you can make an impact, working alongside like-minded individuals and with materials at the forefront of future technologies. Our employees have a unique opportunity to gain experience in all facets of the production cycle including working side-by-side with highly skilled scientists and chemists, contributing to process improvement initiatives, and observing the inception of new molecule processes. We are looking to add talented personalities with a “just do it” attitude to our diverse team who will contribute to our entrepreneurial culture, using and developing their individual skill set and career experience.

In addition to the immediately available positions listed below, we encourage highly qualified applicants to send us their resumes for future job openings: jointheteam@ereztech.com.

Ereztech is an equal opportunity employer and will consider all applications without regards to race, sex, age, color, religion, national origin, veteran status, disability, sexual orientation, gender identity, genetic information or any characteristic protected by law.