Packaging Options for ALD/CVD Precursors

Maintaining purity from synthesis to the point-of-use is of utmost importance to guarantee delivery of the highest quality material for development and manufacturing applications. These materials are often air and moisture sensitive, and require appropriate packaging to interface with different delivery systems.

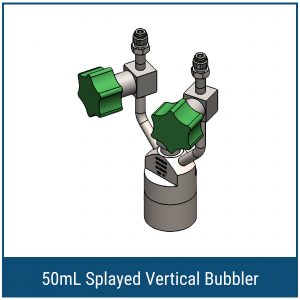

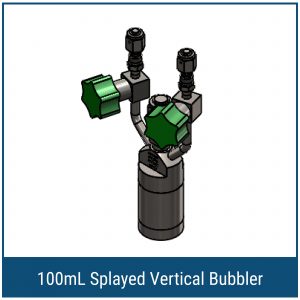

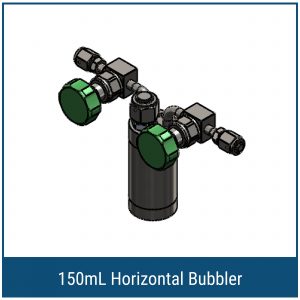

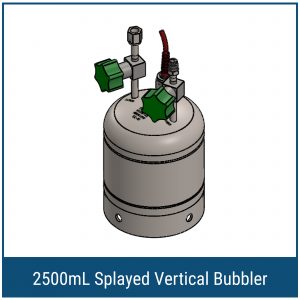

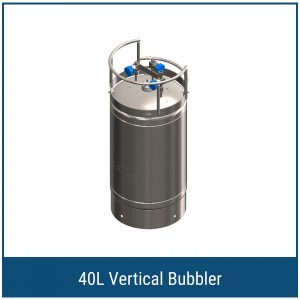

We proudly partner with Precision Fabricators Limited (PFL), a global leader in manufacturing cylinders, bubblers, and ampules, to provide vessels matched to every chemical product’s properties as well as each customer’s application. Canister configuration options support direct vapor, bubbler and direct liquid delivery options starting with volumes as little as 25 to 200cc. We leverage PFL’s 30 years of MOCVD and ALD experience, and over 400 cylinder designs, to provide the best packaging for every synthesis.

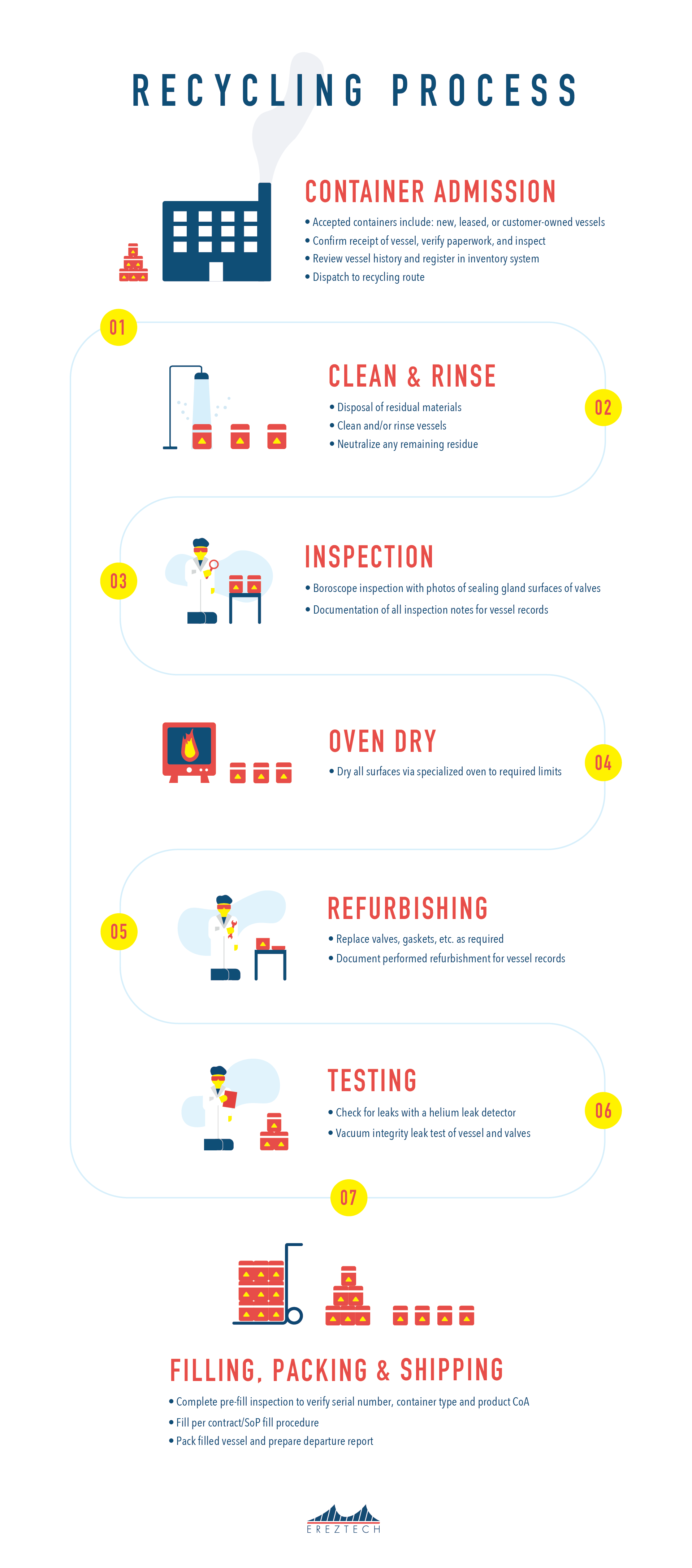

Ereztech Packaging Program

We offer full-service production and packaging, from synthesis samples to high-volume manufacturing quantities, simplifying your process and creating efficiencies for your business. Whether we source your material vessels, or you choose to supply your own, we provide:

- Fully-customized vessel cleaning procedures based upon the materials and their intended use

- Detailed, custom workflow processes specific to each material and vessel

- Comprehensive inventory management system including fill history, inspection reports, and detailed maintenance records for each vessel

- Beginning to end quality control for the preparation and packaging of your organometallic chemical requirements, reducing material handling costs and lead-times

Packaging Selections

We have a wide selection of in-stock, ready-to-use ampules, cylinders, and bubblers. Additionally, we also offer fully-customized packaging solutions to meet your needs, from sample-sized to HVM-sized vessels. Contact us to discuss your packaging needs and we’ll work together to find a solution that works for your manufacturing process.

Available Vessel Types

- Borosilicate glass ampules

- Hermetically-sealed and transparent

- Product may be repackaged if customer has appropriate facilities to safely handle and maintain the integrity of the materials

- Ampule sizes are customized to meet each customer’s requirements

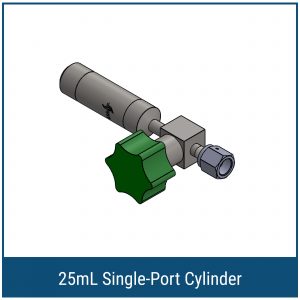

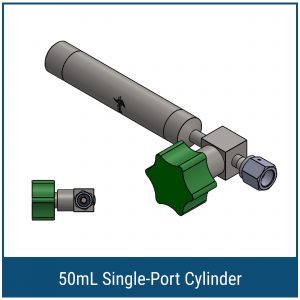

- 316L stainless steel vessels

- DOT-certified with electropolished interiors

- Standard configuration with VCR connections

- Valve options may be customized based upon intended service conditions

- Available in a range of sizes, from small evaluation samples to vessels sized for manufacturing

- Ready to connect to the customer’s delivery system upon receipt

Alternative Vessel Options

- Customer-provided vessels: you may provide your own vessels for maintenance and refilling services following successful completion of an engineering review for suitability

- Leased vessels: let us handle the logistics and maintenance.