Ship-To-Control Consistency in Metal-Organic Precursors

Statistically-Driven Process Control

Ensuring consistent uniformity and quality on precursor lots is not just challenging; for us it is truly mission-critical. We have proven experience achieving Ship-to-Control by leveraging our statistically-driven processes and infrastructure. We achieve Ship-to-Control by executing the following key steps:

- Define the parameters for your custom metal organic compound — its chemical specifications, including its purity level.

- We then review desired parameters through a structured SPC meetings.

- Our Ship-To-Control process uses statistical process control models to create in-control limits for your metal-organic precursor manufacturing processes. If a quality control (QC) parameter deviates from the mutually agreed upon statistical parameters, we will review and implement appropriate corrective measures.

- The end result is desired product and process consistency

To help ensure Ship-to-Control readiness, we implement Ship-to-Control processes into all products with HVM intent at no additional cost.

In parallel to our Ship-to-Control methodology, we collaborate with you to review and enhance processes to sustain continuous improvement.

To find out more about our quality assurance programs, contact us.

Continuous Improvements In Organometallics

But the process doesn’t stop there. We continuously monitor and refine our metal-organics manufacturing processes based on the feedback from our Ship-To-Control program.

This QC feedback loop not only continually reduces process variability for your ALD precursors — it also maximizes production efficiency, enabling us to accelerate your results.

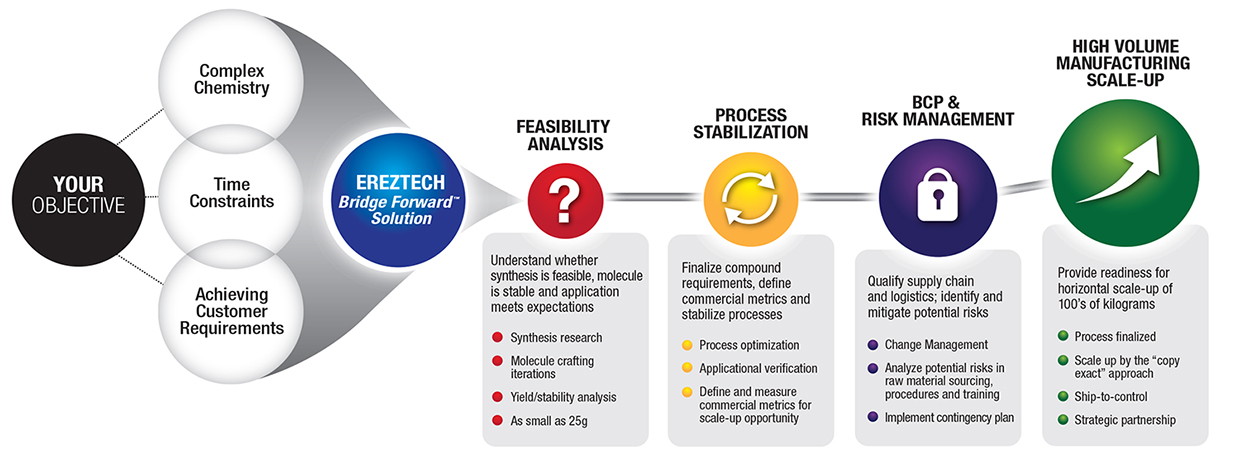

To find out more about our proven methodologies, manufacturing processes and quality assurance approach, visit our Ereztech BridgeForward™ page.