Shipping Hazardous Materials Internationally: Common Mistakes to Avoid

When it comes to shipping hazardous materials, there is a steep learning curve with potentially significant ramifications for incorrectly prepared and labeled shipments. Managing the logistics of different classes of hazardous materials is an essential part of our daily operations at the lab. However, many of our customers rarely, if ever, have to navigate the intricacies of hazmat shipments in their day-to-day operations.

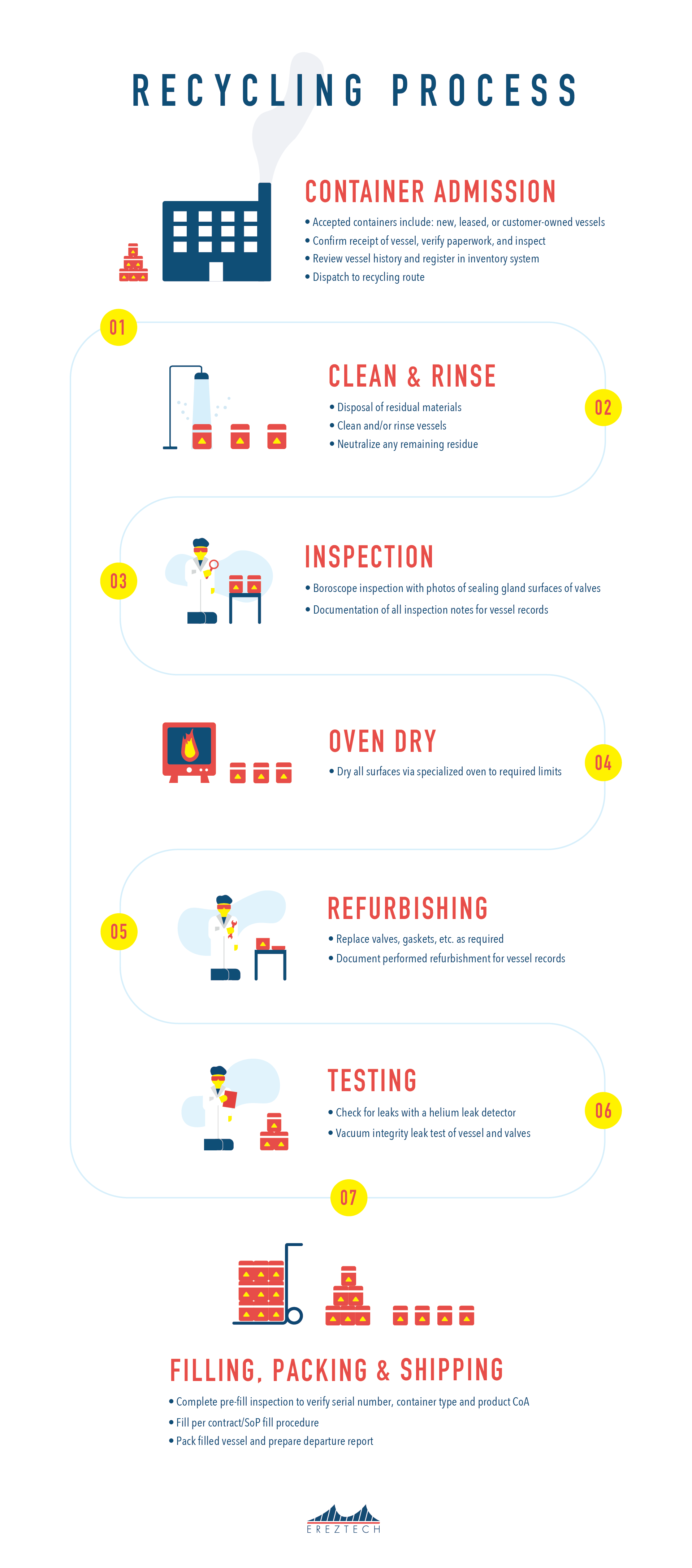

As companies continue to search for ways to reduce their environmental impact, they may look to apply more sustainable practices to their manufacturing processes. To support sustainability goals and reduce packaging costs, we offer our customers our ALD/CVD precursor packaging recycling program for bubblers and cylinders. You can learn more about our recycling program here.

If you’re interested in participating in an ALD precursor package recycling program such as ours, it is crucial to have a thorough understanding of the rules and regulations of hazardous material logistics, along with common mistakes and potential implications for your business.

This is important because within a cylinder and bubbler recycling program, customers have a responsibility to pack and ship the expended vessels back to the lab for cleaning, refurbishment, and refilling. Although the containers may be considered empty, residual materials remain within and therefore must be treated as hazardous materials for packing and shipping purposes.

Review these common mistakes and potential consequences for improper handling of hazmat shipments to keep your employees and logistics personnel safe.

Common Mistakes

Using the Wrong Form of Transportation

When shipping hazardous materials, it is important to identify and understand the hazardous materials class of what you are shipping, especially if the shipment is traveling overseas. Regulations vary drastically between modes of transportation; if intercontinental transportation is required, the method should be thoroughly researched. For example, certain materials, such as those with pyrophoric qualities, are not allowed to fly. Additionally, packing requirements can be entirely different for a hazmat shipment traveling ground versus via air freight. Work closely with your carrier or freight forwarder to determine the correct mode of transportation.

Exceeding Limitations on Hazmat Volumes

Depending upon the transportation mode, allowable volumes of certain hazardous materials can vary dramatically. Limits have been established for various types of hazardous materials due to their nature, with the intention of minimizing the potential impact of leaks or other accidents. Be aware of the limitations imposed by transportation regulatory bodies, such as the DOT, IATA, or IMO. Use your carrier or freight forwarder as a resource for packing guidelines when creating your shipments.

Incorrect Labeling and Declaration

For the safety of all personnel who may come into contact with your hazardous materials shipment, clear and definite identification of the goods is essential. Proper UN hazmat labels and/or placards are required to identify the package’s contents, in addition to correctly completed declaration forms. Familiarize yourself with the classes of hazardous materials, labeling requirements, and declaration forms to avoid potential issues when your shipment departs.

Unfamiliarity with Material-Specific Regulations

It is ultimately your responsibility as an organization to know the regulations for the materials that you ship. Understanding the packaging requirements and allowable transportation methods for each hazardous material shipment leaving your facility is essential to avoid undesirable consequences that come with falling out of compliance.

Consequences

Costly Fines

Improper labeling, packaging, and paperwork for hazardous materials can result in hefty fines due to the risks involved with mishandling or mismanaging the shipment. The governing bodies of transportation, such as the IATA (International Air Transport Association) or the DOT (Department of Transportation), have clearly defined labeling and paperwork requirements for all hazmat shipments. If incorrectly labeled or declared, fines can cost tens of thousands of dollars or result in criminal penalties.

Shipment Refusal

Without a thorough understanding of all the complexities of hazardous materials shipping, you run the risk of having your shipment refused altogether. This can be costly, both financially and time-wise, ultimately delaying your production timelines.

Personal Injury and Environmental Harm

Failure to comply with established hazmat transportation regulations can result in potentially dangerous consequences for all stakeholders involved in the shipping process, from your employees to logistics personnel and beyond. Some hazardous materials may cause severe illness, death, or pose an environmental threat if stored, handled, or shipped improperly.

This blog post is a follow up to a previous post, How to Ship ALD Precursors by Land, Air and Sea, that gives a detailed overview of all things to be considered when embarking on your first hazardous materials shipment.